Closing Manufacturing Loop: 4MP Geometric Feedback Method

WE HARNESS TECHNOLOGY’S EVOLUTION TO REDEFINE POSSIBILITIES

MODERN MANUFACTURERS FACE ONGOING ISSUES THAT REDUCE EFFICIENCY, QUALITY, AND PROFITABILITY

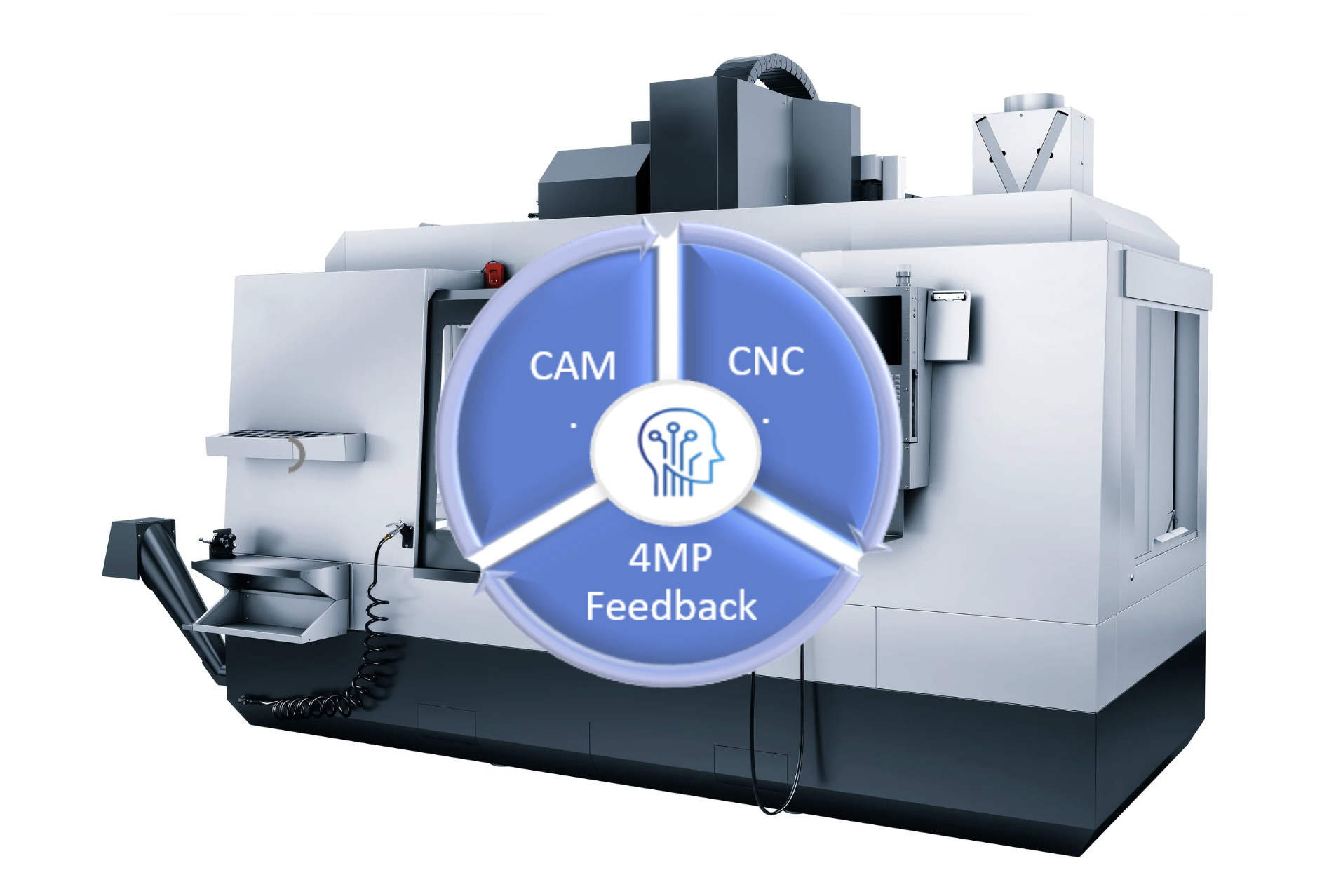

A key challenge is the lack of real-time geometric feedback during machining, leading to longer production times, delayed error detection, and costly rework. Current feedback loops—relying on metrology performed outside of the CNC machine and followed by manual CAM updates—are way too slow, often causing downtime or excess scrap if production continues without immediate insight.

WHY US

Unlike traditional setups, which miss critical machining error sources, 4MP provides geometric feedback that ensures every part—starting from the first—is machined accurately. This not only might reduce the number of machining passes but also boosts throughput and enables the use of simpler, less rigid systems like robots for machining operations.

EFFICENCY, QUALITY AND PROFITABILITY LIKE NEVER BEFORE

4MP Closed-Loop Manufacturing solves problems by delivering real-time geometric feedback directly during machining—without removing the part or the need for skilled operator intervention. The system integrates with CNC machines, reads the CAM data, detects geometric errors in the machined part in real time, and automatically updates the CAM of remaining machining passes to correct for detected geometric machining errors. All updates are stored in a digital twin, and each finished part comes equipped with a quality certificate for full traceability and assurance.